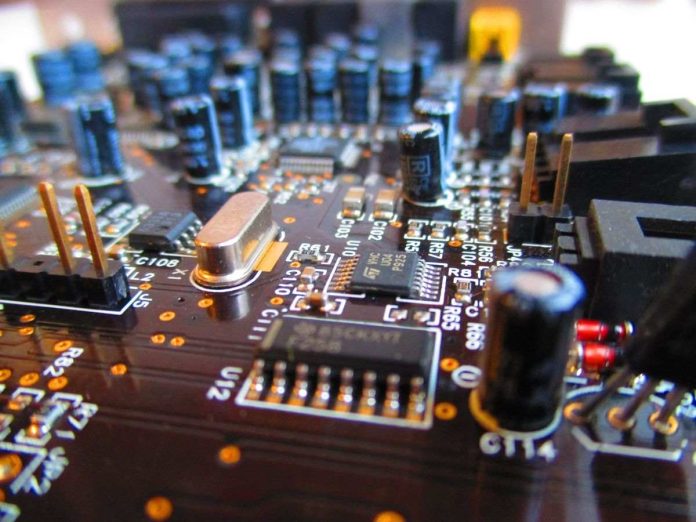

PCB assembly or PCBA is the process of assembling different components on a PCB. It includes placing the components on the PCB and soldering them together.

The process of PCB assembly is divided into two main steps:

- The first step is to solder the components on the PCB.

- Next, the second step is to connect the components by soldering a wire from one component to another.

In this way, each component is connected with other components through a wire or cable, so that it can form a circuit and make contact with other components in order to complete the circuit.

Further, there are majorly two kinds of assembly techniques used in the market which are surface mount technology (SMT) and through-hole technology (THT).

SMT assembly method

The surface mount PCB assembly is a method of assembling printed circuit boards (PCBs) using solder paste. The PCB is mounted on the printed circuit board by either a specialized tool or by hot air.

This is done to ensure that the printed circuit board can be mounted on the mounting board without damage or voiding of solder.

SMT is cost-effective as it needs less human intervention than THT and at the same time, it is much faster. It is highly useful in mass production and where highly durable products are not a top priority.

THT assembly method

This type of assembly method requires a lot of manual intervention. This is greatly beneficial in the production of products that face high voltage and temperature like transformers.

The primary benefit of through-hole technology over SMT is that it allows for easier wiring since there are no spaces between components on the board and also reduces resistance due to crosstalk caused by high-density signals traveling through.

Choosing a PCBA company

PCB assembly is a highly specialized industry, with a myriad of choices and options. It can be difficult to know where to begin when choosing your PCB assembly company. Here are a few tips on how to choose the right one for your project:

1. Choose an experienced PCB assembly company

A good way to determine whether or not an experienced PCB manufacturer has the equipment needed to produce high-quality boards is by checking their website for references from previous clients (one or two quotes are usually enough). Ask them about their process for board design and manufacturing, if it involves multiple steps such as designing in CAD software, then this is a great way to determine the quality of products.

2. Compare pricing

Without any doubt, pricing plays a pivotal role in the pointers to select a company. You can compare the prices online by checking the websites of different vendors. Not to mention, with the help of online quote systems, you can easily find out how much it costs to fulfill your business requirements.

3. Certifications

You should ask for quality certifications from your potential PCBA company as certifications can make or break your business. Certifications such as ISO can make sure that your company is good and equipped with the tools and resources to complete your project on time without compromising on quality.