With the use of the metal-forming process known as powder metallurgy, metal can be reduced to powder and then used to create special materials. The products created with powder metallurgy are hand tools, hydraulics, industrial equipment, and hardware. Many products, including kitchen appliances and ceiling fans, can be made using powder metallurgy.

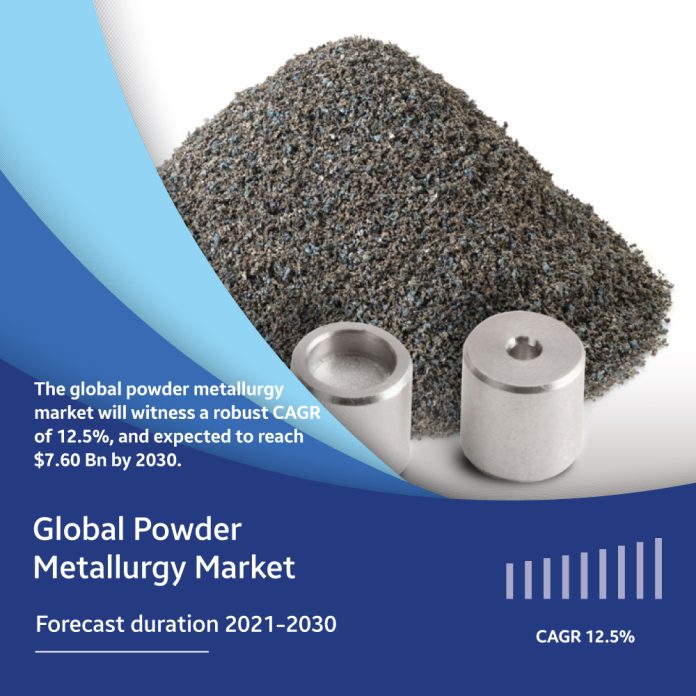

The market worth of powder metallurgy in 2021 was USD 2.63 billion and will reach USD 7.60 billion by 2030, growing at a 12.5% CAGR during 2021-2030.

Market Dynamics

Drivers

Increased government initiatives and urbanization will enhance market growth.

Rapid urbanization and rising disposable income boost customers’ spending power, which raises the demand for consumer electronics items and broadens the market’s potential for growth for vendors and producers of power metallurgy during the projection period. The powder metallurgy market will have progressive growth prospects due to the developing manufacturing sector and rising government initiatives to support that sector’s expansion.

Increasing demand from the automotive industry will boost market growth.

Powder metallurgy is used in the automotive sector for a variety of purposes. The market today demands more than a robust component, and components are now fighting to meet the lightweight requirement due to the changing industrial landscape. The ability of car manufacturers to design mechanical parts with various compositions allows for great precision and minimal material waste. Additionally, the emerging market for autonomous driving vehicles (ADV) is growing in popularity and opening up new markets for high-quality automotive components, particularly in developing nations like China, which has prioritized this industry for development.

Restraints

Metal 3D printers use various materials, including powder metallurgy, to produce various end products. It costs more than materials employed in conventional production processes. The stainless steel used in additive manufacturing is a hundred times more expensive than commercial-grade stainless steel used in conventional manufacturing, costing roughly USD 8.0 per square centimeter.

Opportunities

In order to meet the continuously expanding demand for a variety of drivetrain applications, particularly Powertrain, powder metallurgy includes a wide range of methods with specifically developed metal powders. The PM process chain enables energy-efficient manufacturing of the powertrain components, which results in a green (environmentally friendly) manufacturing process. Therefore, PM/powder metal powertrain components are a highly effective means of cost reduction. This, in turn, will provide several prospects for market advancement in the future.

Market Segmentation

Material Insights

In 2020, the steel segment held the largest market position, with 46.8% of the revenue share, owing to the ease of accessibility and affordability. The expanding usage of steel powder for various applications in numerous industries and the use of steel in the 3D printing of major objects like machinery, automobile frames, and transportation equipment drives the segment’s overall expansion.

Process Insights

On the basis of processes, the market is segmented into additive manufacturing, metal injection molding, Powder metal hot isostatic pressing, and others.

The largest market share was contributed by the powder metal hot isostatic pressing in 2020, with 55% of the revenue share. The demand for PM HIP will increase as a result of the increased machining efficiency provided by PM HIP and the potent combination of improved raw materials.

Application Insights

On the basis of application, the market for powder metallurgy is segmented into aerospace, industrial machinery, electrical & electronics, automotive, and others.

The automotive segment ruled the entire market in 2020 with a 3.8% CAGR. Because of their regulated porosity and self-lubricating capabilities, they can filter gases and liquids and create mechanical parts with a wide range of compositions, such as metal-metal and metal-non-metal combinations. It also allows for the production of automobile parts with extremely little scrap and waste material, exceptional dimensional precision, and uniformity in characteristics and measurements.

RegionalInsights

In 2020 North America held a dominant market position with the largest share of 36.5% due to rising demand from the aerospace and defense industries. Strong defense spending in the United States and the sizeable government and commercial aerospace sectors will fuel market growth.

Europe’s strict fuel efficiency regulations will stimulate the need for lightweight powder metallurgy components in the aerospace and automotive industries. Germany, a leader in industrialization and the adoption of new technologies, ruled the regional European market in 2021. It has 148 research institutions actively working to advance additive manufacturing, which is anticipated to be crucial in boosting the local market’s growth.

Key Players

- Hoganas AB

- GKN Plc

- Sandvik AB

- Carpenter Technology Corporation

- Rio Tinto Metal Powders

- POLEMA

- Carl Schlenk AG

- Allegheny Technologies IncorporatedAdvanced Technology & Materials Co. Ltd.

- American Chemet Corporation

- Hitachi Chemical Co., Ltd

- LIBERTY Steel Group

- ATI

- Metaldyne Performance Group Inc.

- Sumitomo Electric Industries, Ltd

- Miba AG

- Molyworks Materials Corporation

- JSC Polema

The market worth of powder metallurgy in 2021 was USD 2.63 billion and will reach USD 7.60 billion by 2030, growing at a 12.5% CAGR during 2021-2030. Increasing middle-class income, combined with rapid urbanization, drives demand for autos and consumer electronics products, propelling market expansion during the projection period. Furthermore, technological developments and increased investment in research & development are accelerating the growth potential for vendors and manufacturers.