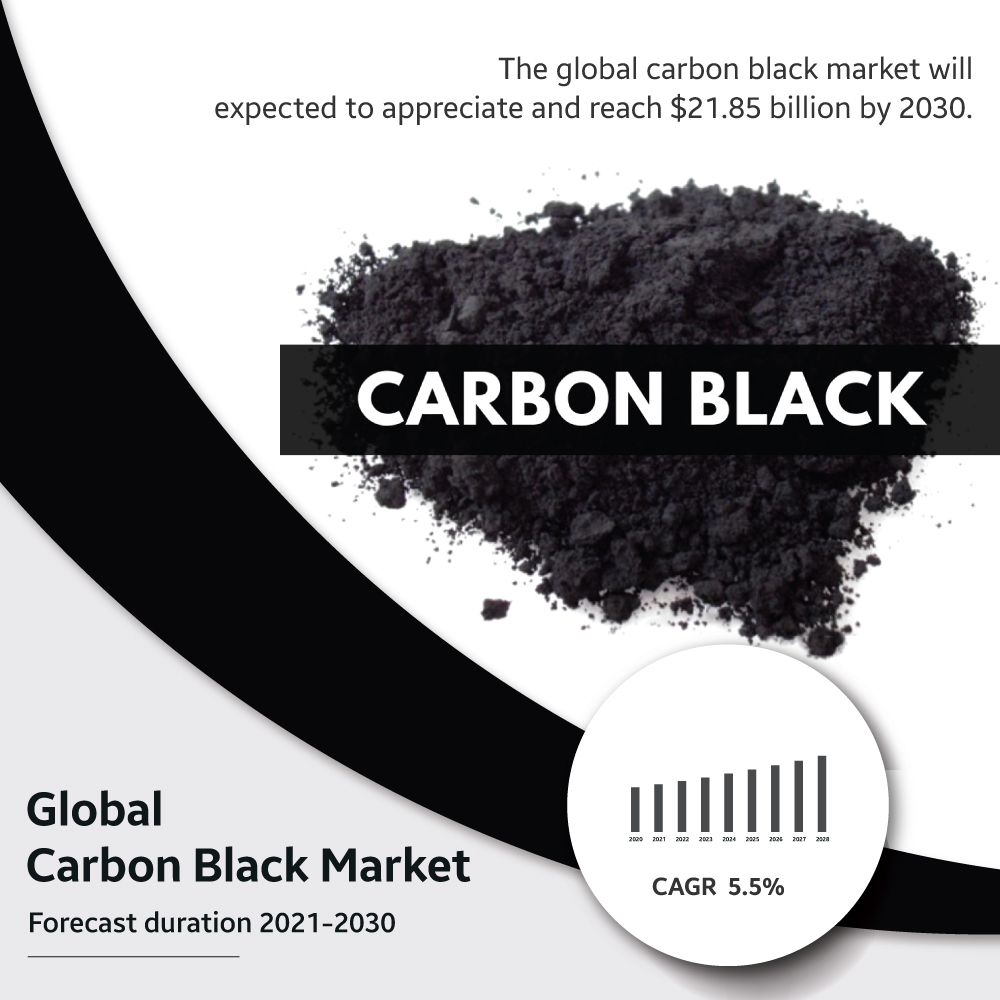

The worldwide carbon black market, estimated to be worth $13.45 billion by 2021 but rising to $21.85 billion by 2030, would experience a strong CAGR of 5.5%.

When coal, plant matter, coal tar, as well as petroleum products like fuel oil, ethylene cracking, and fluid catalytic cracking tar are partially burned, carbon black is produced. Carbon black is defined as a type of paracrystalline carbon with such a high surface-to-volume ratio, however, its surface area is smaller than that of activated carbon. It differs from soot in that it contains far fewer polycyclic aromatic hydrocarbons (PAHs) and has a slightly bigger ratio of surface area to volume (nil and non-bioavailable). Nevertheless, carbon black is widely used as a model substance for diesel soot in studies of diesel oxidation. Carbon black is used as a filler and colouring additive in tires and other rubber products. Carbon black is a colouring compound and wear-protection component used in plastics, paints, & ink pigments.

Market Dynamics

DRIVERS:

- An increase in demand for the substance across numerous industries, including paints and coatings, leather reinforcement, battery electrodes, plastics, and inks & toners, is driving the global market for carbon black. The market of carbon black is driven mainly by carbon black’s expanding use in the tire industry. According to Kordsa Teknik Tekstil AS, the global tire business produced 1.498 billion unit in 2020, an 11.5 percent decrease from 2019. The total volume of the tire industry will reach 1.813 billion units by 2023. As a reinforcement filler, carbon black is easily incorporated into recipes for the rubber used in both tires and non-tire applications.

- In addition, the use of recovered carbon black—an environmentally friendly material made from recycled used tires—has increased. Other examples include conductive carbon black, which is frequently used to improve thermal and electrical conductivity, radar-absorbent materials, which are made by combining carbon black with crystal composite and reduce radar cross-sections, and gum vulcanization, which is frequently used to improve the physical characteristics of carbon black-filled vulcanised rubble.

RESTRAINTS:

The cost of carbon black has been steadily rising over time. According to SMR’s analysis, market growth would drastically decline in 2022 as prices rise from roughly USD 1415 per megaton to USD 1485 per megaton from July through September, and also in 2021 from roughly USD 1,330 per MT to USD 1,365 per MT from January through March.

OPPORTUNITIES

Carbon black is an effective and often used UV stabilizer. In a variety of plastic applications, the pigment uses a UV absorber and particle reinforcement. U.V. stabilizers such as carbon black are added to plastic before it is extruded or molded. The UV stabilisers screen or absorb the damaging UV rays, converting their energy into heat that is evenly distributed throughout the product without causing any harm.

All materials warm up when exposed to the sun because they absorb its rays. Sunlight causes a breakdown in some materials, most notably polymers, even though it has minimal effect on many materials other than simple heating.

Market Segmentation

Process

- Furnace Black

- Acetylene Black

- Channel Black

- Lamp Black

Grade

- Standard Grade

- Specialty Grade

Application

- Plastics

- Tires

- Printing Inks

- Coatings

- Toners

Geography

North America

- USA/America

- Mexican territory

- Canadian Provinces

- Rest of N.A.

Europe

- Switzerland

- Suomi

- Deutschland

- Hungary

- Republic of France

- Netherlands

- K.

- Turkey

- Rest part of Europe

Asia Pacific

- China

- South Korea

- Japan

- India

- Australia

- Remaining APAC

LAMEA

- Saudi Arabia

- Argentina

- Brazil

- Uruguay

- Rest of L.A.M.E.A.

In terms of Process, Furnace Black dominated with a comprehensive share of the market in 2021. Owing to the black furnace process for rubber reinforcing, the market share is predicted to increase. This technique is also used to make colour pigments for cosmetics, as well as its increased utilization is projected to hasten market growth. According to SMR’s research, the cosmetics industry will bring in $100.50 billion in revenues in 2022. The market is expected to grow by 7% annually. The black furnace segment will grow in the worldwide Carbon Black Market as a result of this development in the cosmetics market.

For the Grade section, the market was controlled by standard grade. This is a result of the widespread usage of tires, cables, and other standard-grade rubber-based goods in many industrial applications. The specialized grade segment will experience and foster a high growth rate owing to the rising utilization in the plastic, inks, and coatings industries. During the projection period, it is expected that the market will expand even faster due to the increasing demand for lithium-ion batteries. It is estimated that it will represent 29.25% of the market by 2030.

For Application, the Tires section accounted for the greatest share of the market, but the plastics category is expected to expand & prosper at the fastest CAGR during the forecast period. About 70% of carbon dark’s most well-known uses are as a pigment and reinforcement in tires for automobiles. Carbon black’s capacity to conduct away the heat from the tire’s tread as well as belt region lowers thermal degradation and extends the life span of tires. As the demand for vehicles develops, the automobile market is expected to grow primarily. The aforementioned major factor is anticipated to result in an increase in the demand for carbon black, particularly for tires and seat belts.

For Region, approximately 2.51 billion USD of the total was owned by the carbon black market in North America. The predicted increase in demand for goods, including paint and coatings, molded plastics, wires, and cables, is attributed to the U.S. economy’s recovery as well as rising commercial and auto manufacturing activities.

Key Companies

- Omsk Carbon Group

- Birla Carbon

- Tokai Carbon Co, Ltd.

- Continental Carbon Company

- Cabot Corporation

- Himadri Speciality Chemical Limited.

- Atlas Organics Private Limited

- Philips Carbon Black Limited

- Orion Engineered Carbons GmbH

- Ralson